Manufacture Plastic PP Screw Lid with Ribbed CRC Cap with Induction Seal Plastic Cap for Cosmetic Bottle Package

Basic Info.

| Origin | China |

| HS Code | 3923300000 |

| Production Capacity | 100000/Month |

Product Description

| Item | Value |

| Material | PP |

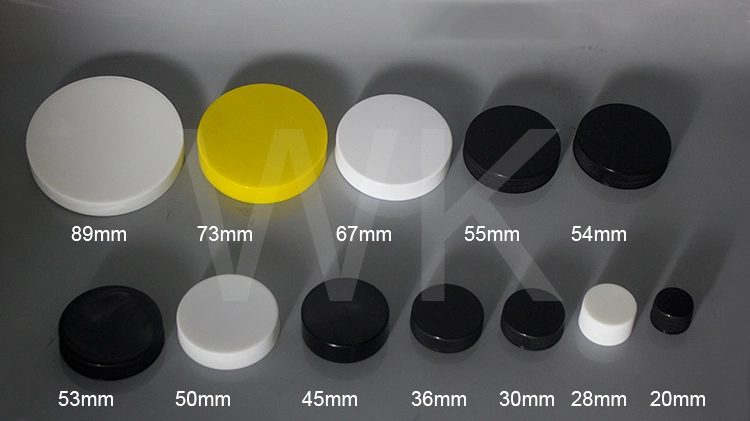

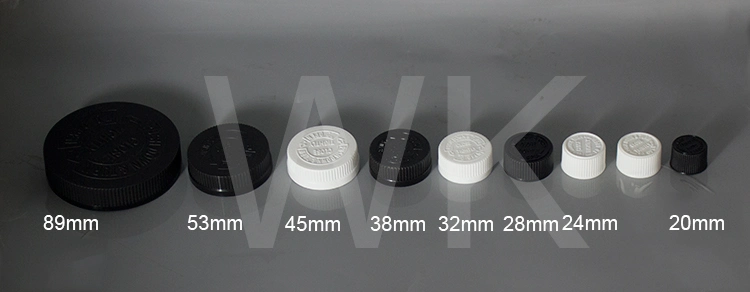

| Type | Screw cap, CRC cap, Flip top cap, Yorker cap, Disk cap |

| Usage | For cosmetic bottles, pill bottles |

| Feature | Non spill |

| Custom order | Acceptable |

| Place of origin | Hebei, China |

| Color | Red, black, white, yellow, pink, blue, green, etc. |

| Logo | Can be customized |

| Sample | Free sample |

| Keyword | Plastic cap |

| Export market | All over the world |

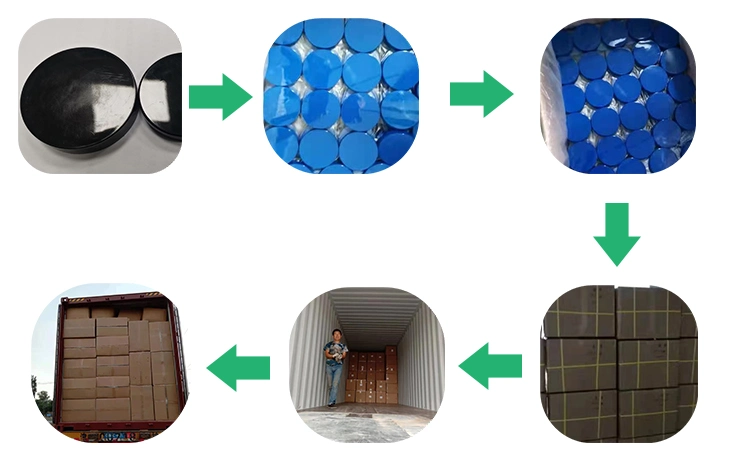

Packaging & Shipping

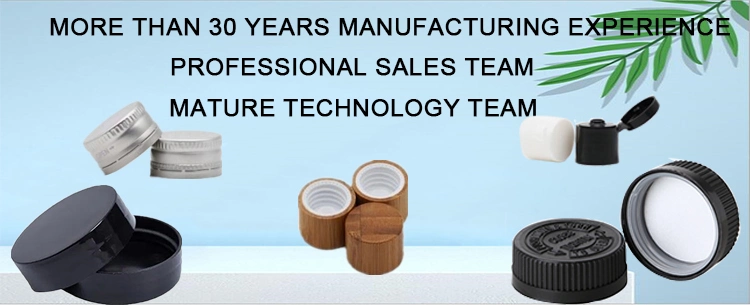

Cangzhou Weikang Package Co., Ltd. was founded in 1986. It is 30 kilometers far away from the ancient city - Cangzhou,which is adjacent to Tianjin and Beijing with convenient transportation access. We have got the registration for solid andliquid medical packing materials and containers granted by state food and drug administration in 2001. Our nationalmedicine package numbers are 20010082, 20020024, 20070679, and 20070674. Our company covers an area of 8600 square meters .We have two sets of 100,000 level cleaning workshop and more than20 sets of advanced equipments ,such as full automatic injection moulding, blow molding, injection and blow moldingequipment. The complete quality testing equipments with advanced technology guarantee the quality of our products .The annul output of medical plastic bottle of solid and liquid can reach at millions. Our products are well-received bothat home and abroad. With the rapid development of high-tech bio-pharmaceutical and medical technology, our company is constantly innovatingbottle design and improving processes. We can also produce new and different products as customer's requirement.To meet the needs of our customers, we offer after-sale services and provide excellent products ,perfect,thoughtful andfast transportation. We are confident to be your reliable partner and wish to maintain long-termbusiness relationship with you. Sincerely hope we can cooperate with you in the near future!Certifications FAQ

Q1: What's your product range?

Plastic bottle: all custom design bottle with different shape and size.

Plastic cap: all custom design jar with different shape and size.

All blowing and injection plastic items.

Q2: What's material plastic you can do?

Material can be PP, HDPE, PET, PS, 475, PCTG, PETG, LDPE, Triton 1001/2001

Q3: Are you an ended manufacture?

Yes, we had been a professional manufacture from 1986.

Q4: Do you sell from stocks?

Yes, If the bottles we don't have, we will make new mold if our clients believe us.

Q5: How should I start with a OEM design( custom design)?

You need to give us a design or a real sample, then we offer to you.

Q6: What do you need to make a new mold for new bottle?

You need to provide the rough shape and size information. Or send us one sample or the draft.

Q7: What information you need to have a quotation?

Your items' height, diameter, weight, material, packaging details, LOGO printing file.

Q8: How long does it take for a mold?

7 days for blowing mold

10 days for injection mold